Each sub-system will be evaluated in terms of the numbers of personnel and equipment required, the reliability and robustness of the sub-system, and the time required to process a single runner. Reliability refers to the reliability of the information that is recorded, at the time it is recorded. Robustness refers to the likelihood that recorded information will survive normal processing and normal (to be expected) mishaps, e.g., dropping cards or tags.

Each sub-system is described as a "single entity" which may be, and, for large races, often is replicated. For example, the manual recording system for a single processing chute is described and assigned a processing rate of 20 to 30 rpm. If you have four processing chutes for a given finish line and are processing runners through each chute simultaneously, the over-all processing rate isfourtimes than for a single sub-system, i.e., 80 rpm to 120 rpm.

As the race size increases, use of bib-numbers (aka competitor numbers) speeds up the process and allows all small races to be handled in this manner. In such cases, finish chutes are not required although they are advised and the electronic timing device is used to provide split times for each finisher in addition tothe "running" time recorded manually. For such races, you may wish to employ a very short finish chute to help sort out clumps of runners. The use of bib-numbers extends this method of directly recording times and runners to peak finishing rates of up to 15 rpm.

For races larger than this, the time/bib-number system is reduced to "select" timing. "Select" timing is also known as "random" timing or "check" timing, among others. Here we will refer to the process of "selecting" and timing certain runners from the stream of finishers FIGURE 2-4. Theoretical distribution of finishers for a "better method yet" approach. Groups of unequal size and different gaps in starting times are chosen to minimize the peak finishing rate. Table V gives groups sizes and starting times. as "select timing." In most cases, select timing is used to insure that the two primary lists of time/place and place/bib-number remain synchronized.

In some cases, select timing is the ONLY timing mode and all runners not "selected" for timing receive "interpolated" times. If this "select timing only" system is employed, it is MANDATORY that "real," i.e., known times, be differentiated or distinguished from "interpolated" times. For record purposes, only real times are valid. If a runner is assigned an interpolated time, the time for record purposes will be the NEXT SLOWER real time! If real and interpolated times are not distinguished, any record will be disallowed.

NOTE that when bib-numbers are used, they MUST be affixed to the FRONT of the runner. Your race flyer/entry blank should state "Wear your number on your front."

Personnel: one required, two recommended

Equipment: stop watch, clip board, pens, paper

Reliability: very good to excellent

Robustness: excellent

Process Rate: 6 to 12 runners per minute

Date Reduction: easy, manual copying as needed

Manual select timing is MANDATORY for all races of any size in order for non-winning times to be considered for record purposes. ALL races should employ manual select timing!

The preferred manual select timing team consists of two persons, one to select and time the incoming runner; the other to record bib-numbers and times as called by the spotter.

The select timing team must be placed at the finish LINE with a clear view of on-coming runners. The select timing team is VITAL to the reliability of the final race results. DO NOT pull them from their position, REGARDLESS of whatever other disasters may be occurring.

Select timers should focus on individual finishers or the lead finishers in a pack. The spotter selects an on-coming runner and reads aloud the bib-number to be recorded. DON'T select people without numbers or with partially visible numbers UNLESS you are selecting EVERY finisher. A time without a matching runner name or number has little value. Quality is more important than quantity.

Select timers can usually time most if not all of the early finishers. As the finishing rate increases, it is important to concentrate on getting a limited amount of GOOD data rather than trying to select time most of the finishers and ending up with a lot of poor data.

As the selected runner crosses the finish, the spotter reads the runner's time to be recorded. If the watch used by the spotter has inaccurate times, i.e., either not started at the start or checked against other watches, the value of the select timing is reduced. If the select timing team is not at the finish line, the selected times will differ from those recorded at the finish and their value will be reduced. Times from digital display clocks should NOT be used for select timing purposes since this creates a lag between seeing the runner finish and seeing the time.

The spotter/timer may wish to take split times and record tenths of seconds. This has several advantages. First, if the watch used is an official watch, the selected times can be used to determine not only the official winning time but also may establish a second split time for an age-group record if that runner is "selected." Second, split times when properly taken at the finish line will be easier to compare with the primary timing device to determine which time in the overall sequence represents the selected runner. Some digital watches now offer a "rapid split action" in which ONLY split times are displayed.

Many electronic timers possess a select time capability (see description under "Time versus Place" later in this chapter) by means of a hand-held pad for entering the bib-number.

Select time sheets should reproduced in ample quantities before the race (see example). Each sheet must have a place for the name(s) of the select timing team to be recorded AND a "sequence" box so that the proper order of the select timing sheets can be quickly determined and any missing sheets easily spotted. Enter ONLY bib-numbers and times on the sheet. Do not enter place numbers or other extraneous information. Bib-numbers should be recorded to the LEFT of the time since bib-numbers are recorded FIRST.

Under rainy conditions, you may wish to enclose the clip-board with select timing sheets, pencil, AND the hand and lowerarm of the recorder in "turkey basting" bags or "dry cleaning" bags. These are made of clear plastic and will permit recording under all weather conditions. Have a supply of such bags on hand, just in case.

Personnel: one required, two may be needed

Equipment: stop watch, tape recorder

Reliability: very good

Robustness: good

Process Rate: 30 to 40 runners per minute

Data Reduction: slow, sequential manual transcription

This sub-system may NOT be used as the only system for recording times and places. It should ONLY be used as a back-up system.

This method of recording runners' times is capable of handling a higher density of runners than the manual select timing and is often used on the course to provide en route information, e.g. to verify that a given runner did indeed pass thru a given check point, such as a turn-around point.

The final product is a verbal record of runners' bib-numbers, times and often comments that may prove useful later in assessing problems. One way of "overlaying" the times on the bib-number sequence is to have a second person calling times at set intervals, such as 5 or 10 seconds, while the first person is reading bib- numbers into the tape recorder.

Another way is to read times into the tape BEFORE the race ever starts. This may be accomplished using a "stereo casette tape recorder" by reading times into one channel and later reading bib- numbers into the other channel (on the two track tape). At the race, the tape is synchronized with the actual race time clock before the first finisher arrives and bib-numbers are read into the second channel. For example, the first finisher in a 10k race is not expected to arrive before 27 minutes. The day before the race, read times onto the tape, starting at 27 minutes and every 10 seconds thru 65 minutes. At the finish line, prepare to start your tape recorder as close to 27 minutes as possible.

When reading bib-numbers into the tape recorder, you should verbalize EACH DIGIT. For example, #1059 should be read as "one," "zero," "five" and "nine."

This system is used to best advantage to provide a runner sequence check at the head of the chutes, particularly if you are recording runner sequence at the ENDS of the chutes.

There are several disadvantages to this system. The information recorded on the tape must be transcribed. This is not only a time consuming process but is also generally not readily available at the race site for other purposes.

Background noise may render much of the information recorded irretrievable. Unfortunately, this is not realized until after the race is finished. Make sure you start with fresh batteries.

Personnel: one required, two may be needed

Equipment: video-tape recorder

Reliability: good to very good

Robustness: very good

Process Rate: 30 to 100 runners per minute

Data Reduction: very slow, sequential manual transcription

This sub-system may NOT be used as the only system for recording times and places. It should ONLY be used as a back-up system.

The best feature of video-tape recorders is that a continuous visual record of the finish adequate to resolve virtually any finish place dispute is provided. The disadvantages are that it is somewhat expensive and does require experienced personnel and planning. This makes video-taping suitable for large and mega-races or races that have sizeable budgets.

Although video-taping the finish is very useful even without time reference points, you will find that being able to reference the video sequence with the proper time is exceedingly valuable. Some video- cameras are available with built-in clocks that can be set to the race time clock. More often, the video- camera is set up so that a digital display clock is in the picture to provide the time reference.

Proper placement of the video-camera determines its ultimate usefulness. Most persons suggest elevating the camera, above and behind the finish line so that a view looking down toward the approaching runners is available. One should attempt to keep the camera close enough to the runners so that bib-numbers are readable, when visible. A tripod or some stabilizing platform makes viewing easier.

Not all runners will be able to be identified by bib-number using this method. It SHOULD NOT be used in lieu of a finish chute to determine runner placement. AT low finishing rates, a majority of bib-numbers will be visible. Some will be partially or completely hidden by clothing, arms and hands, or other runners. For races with higher finishing rates, this becomes more of a problem. When finishing rates exceed 100 runners per minute, you will be fortunate to identify more than 200/a of the finishers by bib-number.

Video-taping is rarely used to provide a complete time/runner sequence. Its principal advantage is in resolving questions regarding proper finish order, back-up select timing and in verifying particular performances such as age group records.

An alternate to a video-camera is a standard camera. One camera that also provides times encoded on the film negative is the Minolta X-700 with the Quartz Data Back system. The operation and use of the standard camera is very similar to that for the video-camera.

Video methods used at the finish are one of the few methods available to identify a runner other than by his/her bib-number. All too often, one runner uses another's bib- number. Many times this is unintentional; sometimes the runner simply decides to run a race for which entries have already closed and "borrows" a bib-number from a legitimate entrant who will not be running.

Make sure you start with fresh batteries and especially for long races, try to have an auxiliary power source.

Personnel: one required, two recommended

Equipment: computer, stable power source, power cables

Reliability: very good

Robustness: good

Process Rate: 6 to 12 runners per minute

Data Reduction: very fast, computer compatible

No finish line should depend solely on a computer for ANY link in the finish system. Such systems should be used ONLY to complement the recommended manual systems.

There are several ways computers can be used at finish lines and there are a wide variety of computers that can be used. Using a computer to provide time/bib-number sequences is a secondary use in large or mega-races since the computer usually is employed to record place/bib-number sequences.

Direct computer entry requires a means of keying in an approaching runner's bib-number and then signalling the computer when that runner crosses the finish line. Clearly, the computer must have an internal clock which can be "zeroed" or "referenced" to the race starting time. The computer then matches the bib-number against a file of name, age/sex and bib-number information for each entrant to produce finish line and award results.

For large races, a partial list of time/bib-numbers may be fed directly to the main computer where the "selected" times are incorporated into the data stream of time/place and place/bib-number so that the final list of times for each runner is properly synchronized.

In small races, where it is feasible to "select" all finishers, direct computer entry is gaining adherents. It has the advantage of producing "instant" race results. It should NEVER be used as the ONLY timing/recording system.

For larger races, the time/place sequence is to be compared to a place/bib-number sequence. The naive assumption is that the 232nd time corresponds to the 232nd runner in the chutes. The time/bib-number sequence completes the linkage and insures that the two primary lists remain synchronized.

Personnel: two required

Equipment: stop watch, clip board, pens, paper

Reliability: very good

Robustness: very good

Process Rate: 30 to 50 runners per minute

Date Reduction: slow, manual transcription

This time-honored method used for scoring cross-country races is fast disappearing. The most common method is to use prepared sheets listing seconds from 0 to 59 vertically with a one inch space to the right of the time for making "tics" or check marks, hence the name "tic-sheet." Each column represents one minute and each column is headed with a space where the hours and minutes may be entered (see example).

The timer reads a finish time for each finisher (and ONLY times corresponding to finishers). Depending on the finishing rate, the recorder either makes tic marks next to the seconds called for each time read (high finishing rates) orthe recorder records bib-numbers in place of a tic mark (low finishing rates). When bib-numbers are recorded, these serve as a "selected" times. You should record bib-numbers whenever possible since these are more useful than tic marks. However, a bib-number or tic mark MUST be recorded for each finisher.

Another method is to write the (sequential) finish PLACE rather than a tic mark. This is

generally used with a place stick or place card method of recording runners and the two

place sequences should be compared as frequently as time permits. This variation allows

a more rapid matching of times with selected runners such as award winners.

FIGURE 3-2

Example of "Tic Timing" form, used to obtain times for all finishers manually.

Personnel: one required, two recommended

Equipment: stop watch, paper, pens, clip boards

Reliability: poor to fair

Robustness: excellent

Process Rate: 6 to 12 timed runners per minute

Date Reduction: easy, manual copying

This method of timing is often employed for large and mega-races where space or other limitations prevent multiple finish lines or other recommended methods of dealing with large or mega-race finishes. It is NOT recommended since it fails to time the majority of the runners properly. Depending on the frequency of the "selected" times, from 90 to 990/a of the runners finishing near the peak finish rate will receive interpolated times.

The select timing only method is used when the finishing rate exceeds the processing rate for the primary timing system. Such races start by timing all finishers, usually with a printing timer capable of finishing rates up to 120 rpm. The select timing also commences with the first finisher and continues throughout the race. As the finishing rate approaches "saturation" for the primary timing system, the primary timing system is either ignored or it is used in a "select timing" mode to supplement the regular select timing team. Once the finishing rate has decreased to acceptable rates after the peak, the primary timing system once again is used to time all finishers.

Interpolated times are not valid for record-keeping purposes. In such cases where a runner betters an existing record, the NEXT SLOWER "real" time is taken for the record. The distribution of runners times between the actual or "real" times is not known. Thus, it is MANDATORY in such cases to distinguish "real" from "interpolated" times. The easiest way is to "flag" the real times in the results (since they are the fewest) and indicate where the select timing only mode began and ended.

Personnel: one required, two recommended

Equipment: printing timer, pens, extra tape, batteries

Reliability: very good to excellent

Robustness: excellent

Process Rate: 80 to 120 runners per minute

Data Reduction: easy, manual copying

The advent of printing timers made it possible to time all finishers in the large races that came about with the running boom in the late l970's. Such devices are so widespread now that virtually all medium, large, and mega-races use them. Printing timers consist of a timing and printing unit with a remote "grip switch" with a push button. Depressing the push button causes the printing unit to print out a split time corresponding to the instant the push button was depressed.

Operators using printing timers can maintain a processing rate up to 120 rpm with "bursts" to perhaps 150 rpm for several seconds. Runners tend to "cluster" so that it might be necessary to punch the button four or five times in one second. In such cases, times may either not be punched or may be "lagged" as the operator "counts" with the push button. Clearly, the timer should be EXPERIENCED.

Another problem results when yanking or bending the grip switch cord causes the signal wires to break. Spurious signals are sent to the timer/printer when wiggling the grip switch cord causes the signal wire to short while the push button is depressed. This results in spurious times being recorded.

Newer printing timers employ a push button with a tactile feedback, i.e., when the push button is depressed, you can feel a click. Earlier models employ a "soft" push button that does not provide this tactile feed-back.

If possible, use a parallel power source to guard against battery failure. NEVER pull on the tape since this may cause the printer to jam. Use the advance wheel. Never "tear" the tape; it should be cut with scissors.

Most printing timers are sensitive to shock. They should be placed on a sturdy platform and kept isolated from crowds of runners trying to read their times.

Some electronic timers have the capability of connecting to a computer, thus allowing recorded times, including selects, to be "dumped" into the scoring program. This feature greatly increases speed and accuracy, and is one of the major benefits of using a computer scoring system.

Personnel: one required, two recommended

Equipment: computer, power source

Reliability: very good

Robustness: very good

Process Rate: 80 to 120 runners per minute

Data Reduction: very fast, computer compatible

No finish line should depend solely on a computer for ANY link in the finish system. Such systems should be used ONLY to complement the recommended manual systems.

Direct computer entry of finish times is very similar in principle to the printing timers with the advantage that the time/place sequence does not have to be transcribed for computer processing of results. In addition, as long as sufficient space is allocated in memory, times will not be lost due to "overflow."

Many computer systems store times to full seconds only. Some "read" seconds and truncate all fractions. Others start at one second and truncate, thereby effectively meeting the requirements of USATF Rule 37.8. For 5 kilometer road races, it is recommended that times be kept to tenths of seconds, taking all non-zero hundredths up to the next full tenth of a second. Refer to Chapter I for handling automatic truncation, rounding off or rounding up.

It is important that all runners who cross the finish line be processed through the chutes. Unofficial runners or interlopers often cross the finish line and exit before being processed. When this occurs, the time/place sequence will not match the place/bib- number sequence. See Chapter IV for details on handling interlopers.

Sub-systems that allow a significant time lag between finishing and processing are down-graded in terms of reliability. Such systems should either be coupled with a second (redundant) place/runner system such as a tape recorder or bolstered with four or five select timing teams capable of recording more than 300/0 of all finishers directly. You should design systems to keep chute build-up to a minimum to reduce position shifting and loss of finish sequence. Keeping the runners moving helps maintain the finish sequence.

The first three sub-systems described are "hand-out" systems, i.e., something is handed to the runner and the runner is expected to act upon it. This is better for short races where runners may be more aware of their surroundings. Hand-out systems typically have higher processing rates and consequently less chute build-up with fewer and shorter chutes than "take-from" systems. The last three sub-systems are take-from systems in which the runner is essentially passive.

The philosophy for handling large fields (high finishing rates) is to divide and conquer. Given a single finish line, the "hand-out" systems are not readily amenable to proliferation. The "take-from" systems are more easily multiplied for parallel processing as in the multi- plex system.

The processing rates given are for SINGLE systems. If you "multiply" or "replicate" your system, you multiply your processing rate. For example, if you have three finish chutes processing runners in parallel and the processing rate given for a single system is 30 rpm, your maximum processing rate is 90 rpm.

Personnel: two required, three to four recommended

Equipment: pre-numbered tongue depressors, clip board, pens

Reliability: good

Robustness: very good

Process Rate: 40 to 60 runners per minute

Data Reduction: very slow, manual recording of verbal information

This system is designed for small races. The real back-up occurs in getting runners to hand in their sticks and get their names recorded. Reliability suffers since not all runners will hand in their sticks. Robustness is very good since runners are "tied" to their place directly.

As each runner finishes, he/she is handed a pre-numbered tongue depressor indicating overall finish position. Care must be taken when processing place sticks that can be misinterpreted by inverting the number, e.g., 86 could be inverted to read 98. Numbers should be written using a laundry marker at one end of the tongue depresser, reading with the blank end of the tongue depresserto the right of the number as properly read.

No more than 10 to 15 place sticks should be held at one time by the person handing them to the runners. A second person should check number sequences and feed place sticks to the person handing out them out as needed. Interlopers (unofficial runners) that cross the finish line should "receive" a place stick, even if the place stick is pocketed by the person handing them out. This helps preserve the time/place/runner matching.

A short chute (5 to 10 meters) may be helpful in sorting bunches of runners to insure that each receives the proper place stick. Once a runner has received a place stick, it is no longer necessary to control the finish order. It is the runner's responsibility to report to a recorder where the place stick is handed in and the relevant information (name, age, sex) is verbally provided and manually recorded. Runners not reporting should be regarded as interlopers and ignored for awards and results.

The processing rate reflects handing out place sticks. Unless another sub-system is also being used in conjunction with the place stick method, the runners waiting to hand in their place sticks can spread out as they please in much the same manner they would await the awards ceremony. This does not contribute to chute buildup since runners could, in principle, hand in their finish stick well after the race is over with and still be properly placed in the final results.

The recording process is slow BUT can be speeded up by using competitor numbers rather than requesting the runner to give name and age, or can be speeded up by utilizing more than one recorder, e.g., places 1-100 report here, places 101-200 report here, etc. In this case, a form of number-blocking or letter-coding is suggested to speed the awards search.

If you have more than 100 runners, you may wish to cordon off an area, requiring runners to pass by check stations where they will be asked to hand in their place sticks. This improves the reliability of the system.

Personnel: two required, three to four recommended

Equipment: pre-numbered 3x5 cards, lots of pencils

Reliability: good

Robustness: very good

Process Rate: 60 to 100 runners per minute

Data Reduction: slow, manual copying of handwritten information

This system operates much as the place stick system with the exception that the runner receives a place card on which the runner fills out his/her name and age on the place card in the space indicated BEFORE turning in the card. This greatly speeds up recording of runners' names. Place cards should be numbered on BOTH SIDES (see examples).

Using two people to alternate handing out place cards facilitates the process. For larger races, one person may serve as a "bank," feeding sets of ten fanned cards to two or three workers who hand them out to the finishers. Interlopers that cross the finish line should "receive" a place card, even if the card is pocketed by the person handing them out. This helps preserve the time/place/runner matching.

Pre-printed place cards may either be pre-numbered or unnumbered. The un-numbered cards are convenient for smaller races since the place numbers can be written in using a water-proof marker prior to race day. Suppose you prepare a set of numbered place cards from #1 thru #999 but only use the first 243 for your race. You can "replenish" your stock for your next race by taking unnumbered cards and filling in numbers 1 thru 243. You can also number in different colors if you have two separate finish lines, e.g., men and women, or two distinct races.

Pre-numbered place cards are intended to be used for larger races. If you have more than one finish line or race distance, you will need to have different colored card stock, e.g., white cards for the 10 km race and blue cards for the 5 km race. This is preferred to using two different number sequences to distinguish between finish lines or events since the awards search will start with separating the two sets of place cards. Errors in this initial sorting are easily spotted if you use different color place cards.

Place cards should NOT have a specified place for the runner's time. This may be inadvertently filled in by the runner and may confuse matters later if an erroneous time is entered.

A short chute (5 to 10 meters) may be helpful in sorting bunches of runners to insure that each receives the proper place card. Once a runner has received a place card, it is no longer necessary to control finish order. It is the runner's responsibility to fill out and hand in the place card. You will need tables with plenty of pencils. You should also employ one or two monitors to answer questions ("What do I do with this card?") and to remind runners to fill out the cards. Again, runners who do not turn in their place cards should be regarded as interlopers.

If you have more than 100 runners, you may wish to cordon off an area, requiring

runners to pass by check stations where they will be asked to hand in their completed

place cards. This improves the reliability of the system.

FIGURE 3-3

Example of "Place Card," used in "hand-out" recording systems.

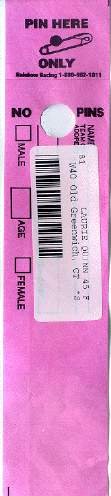

Personnel: two required, three to four recommendedThis system is the next step in sophistication for the "hand-out" methods. Now, all the runner is expected to do is to hold onto a place card for a few seconds. The peelable pull-tag which has been affixed to the bib-number at registration is removed by a chute worker and affixed to the place card. The chute worker keeps the place card. The runner is not permitted to exit the chute with a place card. Place cards are the same as used for the place card only system. Pull-tags should be stapled to the bib-number "points-out".

Equipment: pre-numbered 3x5 cards

Reliability: very good

Robustness: excellent

Process Rate: 60 to 100 runners per minute

Data Reduction: slow, manual copying

Each runner is handed a pre-numbered place card after crossing the finish line, usually at the HEAD of the chute. Cards should be fanned so that only one card is handed to a given runner. One worker (the "bank") may be assigned to "feed" cards to the person or persons handing out the place cards. No more than 10 to 15 cards should be handled at one time. With practice, two or three persons can alternate handing out the cards, each one doing ten, then stepping back, fanning ten more, and so forth. Again, place cards should be given to all runners who cross the finish line.

Processing chutes may be short (20 meters or less) and somewhat wider in this method since runners within a chute may BE PROCESSED IN PARALLEL. Once a runner has received a place card, it is no longer necessary to control finish order. Place several chute workers in the worker lane to collect tags and cards. A given worker picks the closest unprocessed runner and collects the pull-tag and place card. The worker affixes the pull-tag to the place card and "bags" the card. "Bags" may be open-top boxes conveniently placed for two workers to use or may be "nail aprons" tied around the worker's waist.

The "end of chute worker" makes sure cards and tags have been collected from the runners before they exit. Any runner that proceeds this far without being processed, is then processed by the "end of chute" worker. This insures that virtually ALL place cards are collected quickly to speed the awards search and results posting. Runners without pull-tags are instructed to fill in their name, age and sex on the place card. Interlopers' place cards are simply marked "void."

If you wish to replicate this system by employing two or more processing chutes in order to handle higher finishing rates, EACH processing chute should have its own place card sequence. This may be accomplished by simply grabbing the next set of 100 place cards and using these for the newly opened chute.

If you utilize more than one processing chute for a given finish line, you will need to utilize the "chute opening" and/or "chute closing" methods described for the pull-tag/spindle method. Briefly, a "chute opening" peelable label should be carried by or precede the first runner into a newly opened or reopened chute and a "chute closing" peelable label should be carried by the last runner or follow the last runner as a chute is closed. These labels are then affixed to "place" cards since the actual number printed on the card no longer reflects the true overall finish place anyway.

The need for extra processing chutes is limited since the single chute processing rate is usually close to 80 rpm. The recommended solution is to keep the peak finishing rate to less than 80 rpm on any given finish line and replicate finish lines as in the toll booth method. Each finish line would use different COLOR place cards.

Personnel: one required, four or five recommended

Equipment: spindles, chute tags, time tags, unofficial runner tags, substitute tags

Reliability: good to very good

Robustness: fair to very good

Process Rate: 30 to 40 runners per minute

Data Reduction: slow, manual copying

This system requires the runner to do little more than remain in place in the chutes and keep moving forward. It is probably the most popular manual system used today. Pull-tags are removed from runners in their finish order and placed on a spindle to preserve finish order. Note that the individual pull-tags do not have a place or finish order attached. Finish order is determined by relative placement of the pull-tag on the spindle. If pull-tags are not spindled in proper order or if pull-tags slip off the spindle, the finish order is lost. Likewise, without supplementary checks, spindles may be switched or "inverted", e.g., places may be counted from the wrong end of the spindle.

The main advantage is that the system can be easily replicated for several parallel processing chutes capable of handling much larger races. Another advantage is that it does not require any extra effort on the part of the runner. This is particularly important for long races or races held on hot days.

This system, without built-in checks, can be subject to severe problems. It is strongly recommended that most or all of the "safety" features described below, be built into a pull-tag/spindle system. The more safety features you have, the higher the reliability and robustness of your system. Some of the WORST finish line disasters have come from pull-tag/spindle systems. These occur when sufficient supplementary checks are not used and/or the personnel are not trained properly in this method. AVOID DISASTERS! Remember Murphy's Law.

Several types of spindles are available. The best spindle is the "spring-top" spindle which automatically "locks" tags on the spindle. It does require some effort to remove them which is a safety feature. By inserting the "spring" end thru the "loop," you can carry the spindle plus tags conveniently.

Spindles may also be made from coat hanger wire by bending them to form a rectangle roughly 10cm x 25cm (4"xl0") with the long open side extending beyond the rectangle and the short open side bent into a short hook like a safety pin. This serves two purposes. First, the "front" end is obvious and the likelihood of reversing place order within the spindle is greatly reduced. Second, by "closing" the spindle when you are done placing pull-tags on it, you reduce the chances of tags coming off the spindle. Another type of "spindle" is the fish line stringer (available at most sporting goods stores). This consists of a flexible length of braided nylon with a ring on one end and a metal tip on the other. Again, the front end is obvious. The metal end of the stringer can be looped and tied through the ring, thereby "locking" the stringer against losing tags.

If more than one processing chute is used for a given finish line, you will need to use chute tags to identify the spindle sequence. Usually, one spindle is used for a single batch of runners in a given chute. Since the suggested methods for switching chutes and identifying the switching order are the same for any multiple processing chute (multi- plex) system without regard to the particular subsystem used, the discussion of chute operation in the following chapter should be referred to.

The chute tag illustrated has a place for the approximate time of the first finisher in that chute. This serves as an additional check of both the chute number AND the matching of runners and times. In addition to a person responsible for opening and closing chutes, a second person is responsible for the chute tags.

Chute tags are handled in one of two ways. If you have a limited number of personnel, the chute tag may be handed to the FIRST runner entering the newly opened chute who then gives it to the pull-tag collector at the end of the chute. With more people available, you can use workers to carry the chute tag instead of a competitor who might just throw your chute tag away.

Some systems employ both chute opening and chute closing tags. Chute closing tags work in the same way that chute opening tags do. They also provide redundancy to make sure separate chute sequences within the same physical chute are KEPT separate.

Time tags should also be used to keep spindles in their proper order and provide preliminary times for your awards ceremony. Time tags are pre-printed and have times hand-written on the tag, every ten to twenty seconds, e.g., 35:20, 35:30, 35:40, etc. The first runner finishing AFTER 35:20, is handed the 35:20 time tag. That time tag is spindled just ahead of that runner's pull-tag. By making the time tags a different size or different color from the pull-tags, they will stand out for ready identification.

If you are using time tags every ten seconds, it is recommended that two workers be used with ALTERNATING series of time tags, e.g., one worker has time tags 35:00, 35:20, 35:40, etc. on one hoop; the second worker has time tags 35:10, 35:30,35:50, etc. on the other hoop.

Time tags are NOT an adequate substitute for manual select timing. You should ALWAYS employ manual select timing. Time tags are intended to provide quick estimates of times for runners ON RACE DAY.

Another "safety" procedure is for a chute worker with a waterproof marker to mark a sequence number within that chute on the pull-tag while the runners are awaiting processing in the chute. This can help catch errors such as reversed "batches" of pull- tags which may fit in between time cards.

Runners without bib-numbers and/or pull-tags need to be accounted for in order to help preserve the runner/time matching. The "interloper" tag for non-registered runners is placed on the spindle when a numberless and unregistered runner is encountered.

If a numberless runner is encountered who claims to be registered, a "substitute" tag should be used. The example shown is perforated so that a "fill-in" portion can be handed to the runner to be filled out and handed in later. The remaining section is spindled to preserve finish order. If the tag puller has to fill out a blank tag before spindling, the process rate is greatly reduced, something to be avoided. If interloper and substitute tags are not used, properly matching runners and times is very difficult.

The person assigned to be the tag-puller needs to be well briefed and experienced. Tags should be pulled and spindled INDIVIDUALLY. NEVER gather two or more tags before placing them on the spindle. It is very easy to reverse order. This is a ONE PERSON operation. You should NEVER have two persons collecting and spindling pull-tags for a given processing chute. One person may be assigned to guide and hold the runners while their pull-tag is collected by the collector.

You should NEVER use boards for posting places (place boards) to preserve pull-tag finish order in this type of system. That may work fine with place card/pull-tags since each pull-tag has already been "tied" to its place. In the pull-tag/spindle system however, this is not true. The ONLY record of finish order is the sequential placement of pull-tags. This must be preserved, otherwise you have nothing. Do not take unnecessary risks. You may "fan" the pull-tags and use masking tape on the reverse side to hold them in position WHILE STILL ON THE SPINDLE. These then may be "posted" for viewing on race day.

FIGURE 3-3

Example of Bib-Number with a Detachable Pull-Tag.

Note that the pull-tag has the bib-number with corresponding pre-printed barcode, and spaces for runner's name/age/sex information.

Example of alternate Detachable Pull-Tag bibs.

The smaller tag can be attached to non pull-tage numbers, or worn alone. Note that it has a pre-printed address label with runner information and barcode. However, it lacks any numbering of its own.

FIGURE 3-4.

Examples of "Spindles" for collecting pull-tags.

(a) is a "spring-top" spindle; (b) is a "coat-hanger" spindle; (c) is a "fish line" stringer.

Personnel: one or two required, three recommended

Equipment: clip boards, pens/pencils, recording forms

Reliability: good to very good

Robustness: very good to excellent

Process Rate: 20 to 30 runners per minute

Data Reduction: easy, race day results possible

The most common variation of this system utilizes a caller and recorder at the end of the processing chute where runners are exiting. The caller reads each runner's bib-number to the recorder. The recorder enters the bib-number on prepared forms.

The finish order recording forms may simply be lined sheets or may be lined and blocked as in the illustration. In the example shown, place/time tapes from a printing timer (Heuer in this case) are intended to be taped adjacent to the recorded bib-numbers, i.e., the form has been designed to match the spacing between adjacent times from the printing timer tape. Note that the columns to be filled in by hand are CENTERED so that right or left- handed persons may rest their hand on the clip board while writing. An example of such a recording sheet with matching printing timer tapes is shown.

The caller should stand IN the processing chute, controlling the flow of runners out of the chute. The caller will read aloud the bib-number (and letter code if present). The caller should verbalize each digit, e.g., #659 should be read as "six," "five," and "nine," rather than as "six hundred fifty nine."

When more than one processing chute is used, it is necessary to use chute cards as described in the pull-tag/spindle system. A chute card is used to identify each "batch" of runners, i.e., those runners who finish between one "switch" and the next. Each batch should be identified by a LETTER which is written on the chute card. As described in the next chapter, the chute card is given to the chute plug (see Glossary) for the newly opened chute. The chute plug carries this down the chute to the recording team.

When the caller encounters a chute plug (or a runner) with a chute card, the caller says "New Batch" and then the batch letter. The recorder starts a NEW sheet and enters the batch letter at the top as given on the chute card. If more than one recording sheet is required for a single "batch" of runners, the second sheet would be indicated as B-2 for batch "B" sheet #2. The overall finish order is determined by ordering the sheets by batch letter and by number within each batch if more than one sheet is required for a single batch. Each recording sheet should contain enough lines to record the maximum expected number of runners contained in one batch.

If runners without bib-numbers are encountered, the space is filled in with a slash, a "zero", or with "X"s according to individual preference. Note that you MUST account for all finishers in order to help preserve time/place/bib-number matching.

If the ends of the processing chutes are side-by-side, adjacent teams will "conflict" as a recorder may hear several callers. The ends of the processing chutes should be staggered to help avoid this problem.

Personnel: one required, two recommended

Equipment: bar code reader/computer, power supply

Reliability: excellent

Robustness: good to very good

Process Rate: 20 to 35 runners per minute

Data Reduction: very fast, computer compatible

This high-tech approach is designed for races utilizing computers at the finish area. Many personal computers can accept input from light pens reading bar codes and their printers can produce UPC Bar Coded pull-tags plus printed information for manual recording. It is strongly suggested that you utilize a back-up system such as the place card/pull-tag in case of computer failure. If the pull-tag can carry the bar code AND be peelable, the advantages in processing time from the place card system can enhance the computer compatible recording AND still provide a back-up if the computer/bar code system fails to function.

Two cautions should be noted. DO NOT attempt to read bar codes directly pinned to the runner. The bar code information should be REMOVED from the runner before attempting to read it. To preserve finish order, collected bar codes may be skewered on a spindle as in the pull-tag/skewer system OR gathered on a place card as in the place card/pull-tag system.

Avoid high ambient light levels, i.e., out-of-doors. Most finish areas have enough light to confuse the bar code reader, slowing if not stopping the recording process. Best results are obtained when batches or strings of bar codes are carried indoors where they are read.

| Go to Next Section: | Design of the Finish Line System |

| Previous Section: | Finish Line Theory |

| Back to: | Table of Contents |